MechAero, Inc.

Instrumentation and Control Systems

Data Acquisition and Control Systems

Test cell data acquisition and control systems we have designed, developed, and manufactured are capable of digitizing information from over 40 input channels at acquisition rates of 50 samples per second. The system digitizes information from a variety of analog sensors including temperature sensors, speed sensors, pressure sensors, and angular position sensors in a rack mounted signal-conditioning unit. Digitized information is transmitted to a high-speed processor unit via ether net where the data is stored in a database. The database is accessed by a windows based data analysis program which provides real time display to engine under test sensor information, analysis of engine under test condition, and passage or failure results of various performance tests, and a post processing capability. The post processing capability allows an operator to change any of the constants or data points which make up a engine run and reprocess the data to determine updated passage or failure results. The test cell data acquisition system is comprised of a signal conditioning unit (which digitizes the recorded analog data), a processor unit, 18” LCD with touch screen for operator interface to the system, 15” LCD display, keyboard, mouse, printer, and backup power supply.

Data Acquisition System Installed in Navy T-23 Jet Engine Test Cell

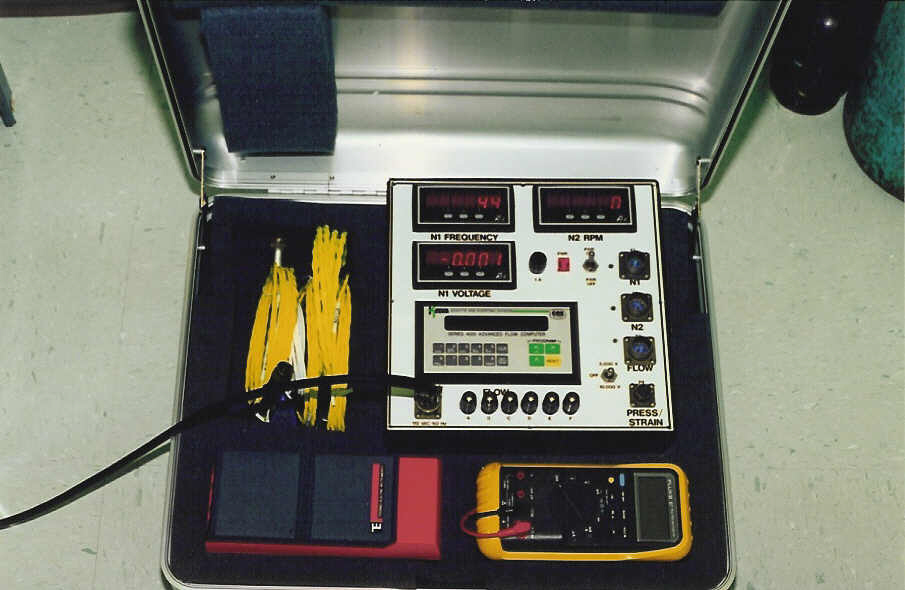

Flight Line Engine Test Equipment for F22 Aircraft

Under a contract with Pratt & Whitney flight line engine test equipment for the F22 aircraft was developed and fielded. The test equipment delivered under the contract was capable of measuring and simulating engine speed signals, measuring engine temperature signals, and measuring outputs from pressure transducers.

Flight Line Engine test set for F22 Aircraft

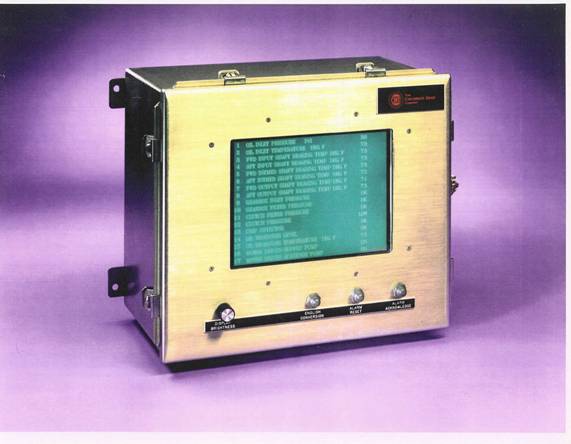

Automated Control and Instrumentation Systems

Control and Instrumentation System we have developed and manufactured are used for automated control of a turbine/gearbox units used in TF-40B powered high-speed ferryboats. The control system automatically engages and disengages the gearbox, shuts down the turbine, and closes various valves. The system displays 17 parameters for each of the two turbine/gearbox combinations under the systems control (34 parameters total). The system consists of two engine room control boxes (one for each turbine/gearbox unit) and a single LCD instrumentation display, which is located on the bridge of the ship. An engine room display and control panel is depicted in the picture below.